Koskisen’s plywood and chipboard have received an Environmental Product Declaration (EPD), a certified document that communicates information about a product’s environmental life cycle impacts. An EPD provides information on, for example, the emissions resulting from the manufacture of the product, the product’s environmental impacts, use of resources and land use.

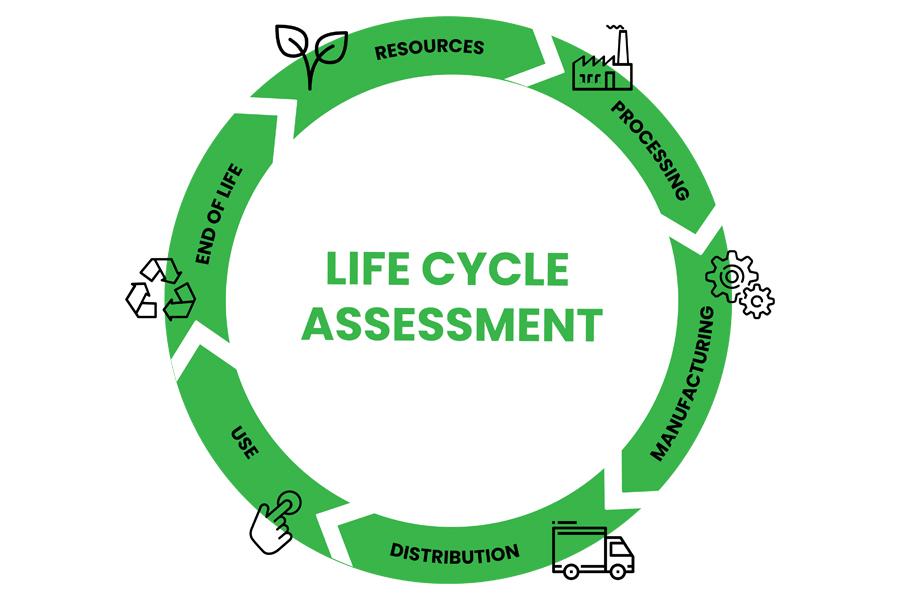

An EPD is a standardised way (EN 15804 + A1) of reliably presenting relevant, verified and comparable information about a product’s total environmental impacts, based on a life-cycle assessment (LCA). EPD calculations are always verified by a third party.

EPDs help understand environmental impacts

Construction product EPDs help contractors, developers and designers better understand the environmental issues related to construction products and materials. The life-cycle environmental impacts of products are important criteria when selecting materials and calculating the carbon footprint of buildings.

The environmental impacts arising during the life cycle of a product include, for example, their impact on climate change, which takes into account the carbon footprint, ozone-depleting substances, emissions that cause acidification of the soil and water systems, emissions that cause eutrophication, and the depletion of non-renewable energy resources and material streams.

Koskisen’s plywood and chipboard were granted EPDs

Koskisen has drawn up EPDs for the following panel products: uncoated birch plywood KoskiStandard, phenol coated birch plywood and uncoated chipboard and melamine coated chipboard.

The Finnish Building Information Foundation RTS has verified the environmental product declarations and they can be found on Koskisen’s website and on RTS’s website.

• KoskiStandard birch plywood: 291 kg CO2-eqv/m3 (-870 CO2-eqv/m3)

• Phenol coated birch plywood: 438 kg CO2-eqv/m3 (-675 CO2-eqv/m3)

• Koskipan; uncoated chipboard: 294 kg CO2-eqv/m3 (-878 CO2-eqv/m3)

• KoskiMel; melamine coated chipboard: 398 kg CO2-eqv/m3 (-740 CO2-eqv/m3)

The products’ global warming potential has been calculated for the product stage that includes raw materials, transportation to the mill and manufacture. The amount of carbon sequestrated in the products after their manufacture is given in brackets; in Koskisen’s case, this figure is negative. This is due to the fact that wood sequestrates more carbon dioxide than any other construction materials.

Wood reduces carbon dioxide concentrations in the atmosphere also as a construction material

There are two possible ways to reduce the carbon dioxide concentration in the atmosphere: either by reducing or removing emissions or storing carbon dioxide. This can be done by reducing the carbon sources and increasing the carbon sinks. Using wood as a construction material covers both.

The use of wood makes forest management more efficient, which makes the forests grow better, sequestrating more carbon dioxide and releasing oxygen. When comparing different construction materials, three factors need to be taken into consideration: the manufacturing process of the material and product, its ability to save energy during its life cycle, and the recycling and final disposal of the product. Compared to other construction materials, wood sequestrates more carbon dioxide. Each cubic meter of wood that is used to replace other construction materials removes an average of 1.1 tonnes of carbon dioxide emissions from the atmosphere.