Sustainable forest management

Koskisen’s Wood Procurement

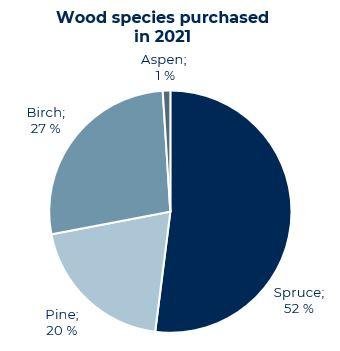

Wood is the main raw material used by Koskisen. In 2021, the volume of procured wood was 1.6 million cubic metres. Of this volume, 52% was spruce, 20% pine, 27% birch and 1% aspen in 2021.

In 2021, the volume of wood used at our own plants was approximately 1 million m3. The share of certified roundwood was 78%.

Koskisen’s Wood Procurement is in charge of the mills’ raw material supply and also delivers wood to other operators in southern Finland. Most of our wood comes from Finnish private forests, mainly in southern and eastern Finland (Häme, Uusimaa and Etelä-Savo). We currently get wood only from Finland.

In addition to the production units’ operations, Koskisen’s wood CoC systems and the ISO 14001 environmental standard ensure the level of control of the origin of wood in all of the countries in which the Group procures wood.

Koskisen’s Wood Procurement is also responsible for the Group’s forests and manages forests for several private forest owners.

Our wood procurement subcontractors have also committed to following the operational system requirements.

Sustainable, long-term forest managemen

Sustainable forest management ensures that there is enough wood raw material for future generations. We always know the origin of the wood and ensure that our forest management practices enable the forest to regenerate and protect natural diversity.

Koskisen Wood Procurement complies with the requirements of the PEFCTM CoC and FSC® CoC chain of custody certificates. These ensure that the wood is harvested from sustainably managed forests where felling is carried out in accordance with the law and certification criteria. The origin of the raw material is inspected based on our procurement policy to ensure forests in protected areas are safeguarded and that wood is not procured from controversial sources.

Our forest management measures always take into account the valuable habitats described in the Nature Conservation Act and Forest Act. Our business relies directly on forests. Consequently, taking care of nature and the environment is especially important for us.

Accounting for natural diversity in forest management guidelines

We follow the forestry development centre Tapio’s forest management recommendations. It is a guideline on financially, ecologically, socially and culturally sustainable forest management practices created jointly by forestry sector operators.

The best practices for sustainable forest management that aim to preserve the diversity of nature include preserving valuable habitats and the living areas of endangered species, and leaving retention trees and deadwood in the forest during harvesting.

Controversial sources:

- Illegal logging

- Logging that violates indigenous peoples’ rights or other human rights

- Forests where important environmental values have been threatened or destroyed

- Natural forests that have been transformed into plantations

- Forests containing genetically modified trees

Wood is a renewable and biodegradable raw material

Careful utilisation of raw material is a benefit to both our mills and the wood sellers.

We use the whole tree. We turn logs into plywood, sawn timber products and other products. We deliver pulp wood to paper and pulp manufacturers. We utilise logging residues as biofuel whenever possible. We use side streams from our production processes as fuel in heating plants. Our products are recyclable, as are most of the packaging materials we use.

We utilise woodchip and sawdust from our woodworking operations in our chipboard production. In addition to wood, we use various adhesives and coatings in our chipboard and plywood production. Our sawmills and planing mills use Finnish spruce and pine logs as raw materials.

We promote the use of products made from a sustainable raw material. Our R&D activities identify new applications for our products and new solutions that attend to environmental needs. Zero Panels, for example, is a fully natural, wood-based product family with no formaldehyde!