Koskinen’s chipboard factory in Järvelä is a kind of unicorn in its field. It is the only chipboard factory in Finland and is flexible to a wide range of chipboard and furniture board needs, as well as customer-tailored batches and special solutions.

Sami Santala, who works as a technology manager at Koskinen, describes the chipboard factory as agile. “We can maintain a completely unique product palette and tailor panels to customers according to their wishes,” says Santala.

Santala says that the factory produces trial batches of special panels for customers at a low threshold. “Standard products and large batch sizes are of course cost-effective, and that is why Central European chipboard factories are focused on them. But we are happy to challenge ourselves and develop the product together with the customer.”

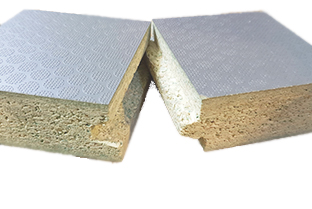

The chipboard factory’s product range is extensive. Different panel thicknesses can be made seamlessly from three millimetres to 50 millimetres. The density of the chipboard can also be tailored to the customer’s needs. According to Sami Santala, in addition to standard products, the technical properties of the board can be optimized beyond the standards according to the customer’s wishes – this is how KoskiPro products are created.

“We can also combine plywood production if necessary, in practice we have all plywood coatings available. That is also unique, that both solutions can be obtained under one roof”, Santala states.

Developing small batches together with the customer and small batch production brings advantages to Koskisen’s customers. When the customer does not have to order large batches of chipboard, it also does not need to be stored at the customer’s end. Product Manager Heidi Pesonen reminds us that Koskisen’s product portfolio can provide replacement chipboard products for various applications for many customers.

“We have many customers who deal with us weekly. I dare say that our customer experience is extremely good”, Santala adds.

High-quality chipboards with a wide range of products

In chipboard production, a type of cake is formed from the raw wood material, which is pressed into a board. The basic density of Koskisen chipboard is denser thanks to a special spreading technology. This ensures the good workability of the boards.

The chipboard factory uses one-daylight press method, which allows for quick switching from one product to another, small batches and a diverse product range. Koskisen chipboards are also of exceptional quality, Heidi Pesonen adds.

“We must always remember to mention quality when talking about our chipboard. We get the raw material from the side cuts of our new sawmill, which is free of impurities. For example, it is completely free of sand and minerals.”