Koskisen’s future sawing line represents world-class product development that also takes into account future needs. Tuomo Kauppinen, sales manager with HewSaw, the company that delivers the line, is nothing less than shocked at how good Koskisen’s new sawmill will be.

Discussions concerning Koskisen’s and HewSaw’s joint project started back in 2015, when boosting the sawing line’s yield was set as a main goal of the future investment. The plans were to build a sawmill with a movable saw assembly, and North American sawmills were the place to start looking for an example.

“The intention was to check out references in other places too, but those plans were cancelled due to Covid,” recounts Kauppinen.

Although six years have already passed since the first drafts were drawn up and the investment is running full steam ahead, the final plans are still not locked down. Kauppinen speaks of the company’s continuous product development and about the upgrades that are to be introduced in the machinery currently in production and which will be applied to the line to be delivered to Koskisen.

“I believe that the line, equipped with the latest bells and whistles, will be perfect for Koskisen. Looking at all the drawings, I’m almost afraid at how good it will be,” says Kauppinen with a laugh.

All the bells and whistles

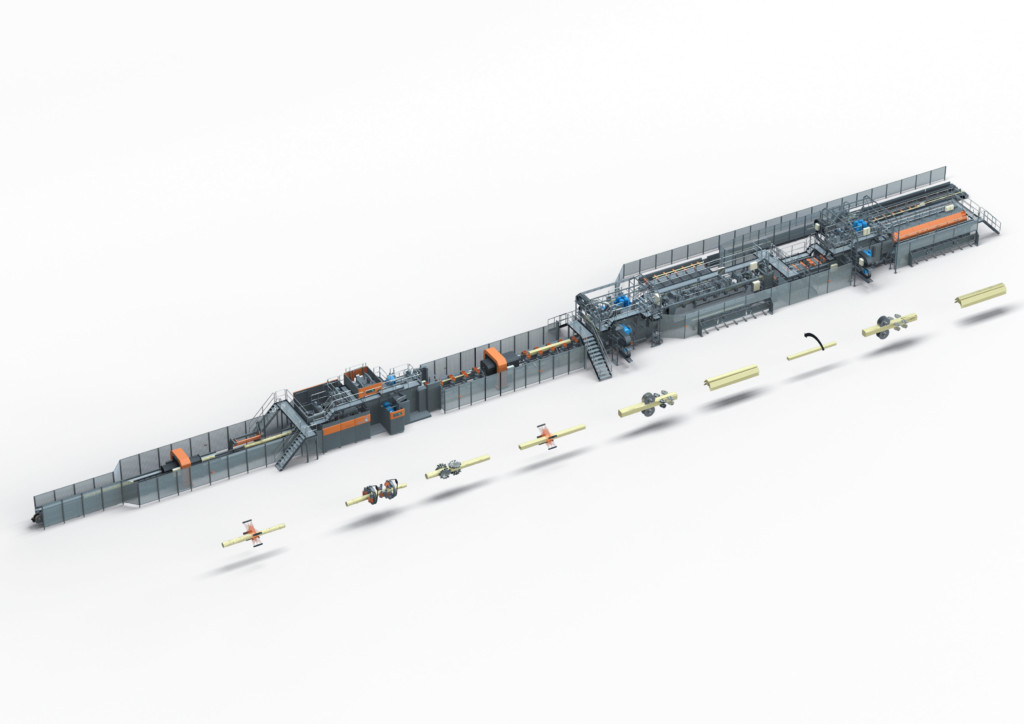

At the heart of the plan is the large-log SL250 sawing line, which includes three machines: a chipper canter, cantsaw and ripsaw. The sawing line is 85.6 metres long in total, and so far no other sawmill has a setup that compares.

Kauppinen lists all of the line’s productivity-enhancing features, such as Prologic’s sorting and optimization scanners, log spacing control, log rotators, curve sawing, optimized edging, high feed speeds, movable saw assembly and fast setting changes.

“The chipper canter’s chipper heads has also been made from special steel for some time now. The blades used to be made of the steel used in aircraft landing gear, but nowadays a better material is used,” says Kauppinen with a chuckle.

The sawing line also comes with the DX option, which makes it possible to ramp up the line’s speed and use thinner kerf saws.

“More efficiency can also be achieved by adding circular saw blades to both the cantsaw and the ripsaw. Thinner kerf saws result in either a higher yield or a longer interval between blade changes. In Koskisen’s case, this would mean a production increase of as much as 200,000 cubic metres.

The line’s maximum speed is 180 metres per minute, but with DX sawing, the speed could even reach 230 metres per minute. However, faster speeds are not the goal, since Koskisen’s line is meant for sawing larger logs.

Pioneering projects that use the latest technology, like this investment, are important not only for the sawmill, but also for the machinery supplier.

“It’s great to be able to make a sawing line for a Finnish sawmill. It is a combination of Finnish work and expertise, and the product development will be easy to continue even after the line is delivered, since we’re working on home ground. This finely tuned sawing line is also an important reference for us globally,” Kauppinen sums up.