Koskisen’s rapidly advancing sawmill investment will bring changes to the day-to-day work of the sawmill’s employees and the sawmill’s internal logistics. But changes are also in store for the sales department, as the future sawing line will offer customers options that were previously not available.

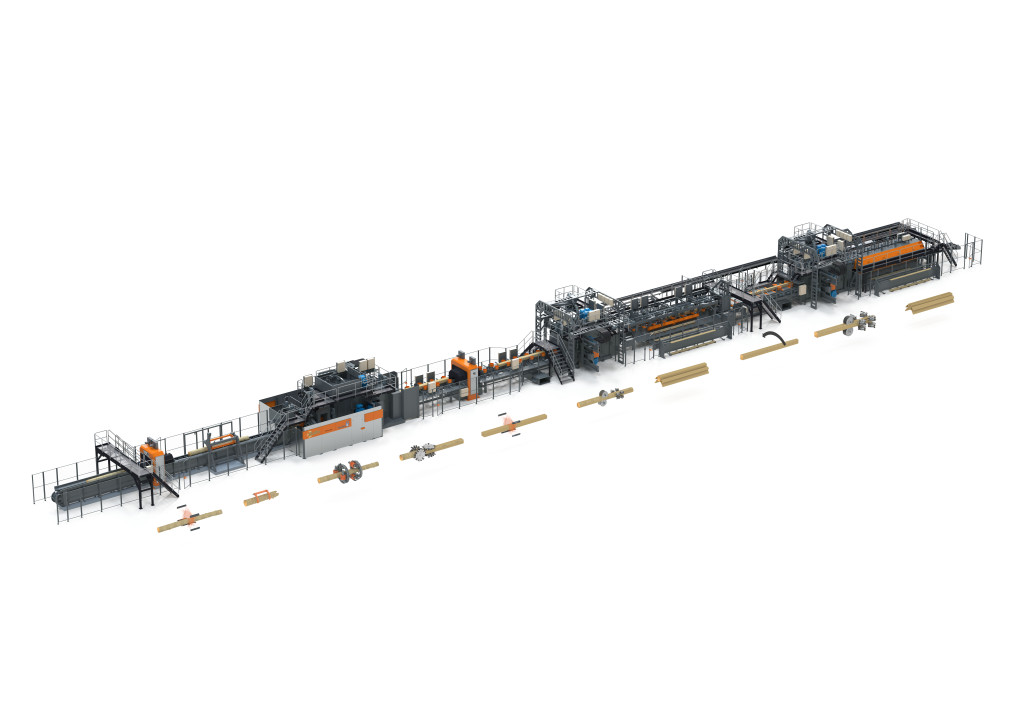

The new sawing line is being built around HewSaw’s large-log SL250 model, which includes three machines: a chipper canter, cantsaw and ripsaw. The sawing line is 85.6 metres long in total, and so far no other setup quite like it exists anywhere. The new line will feature all functions to boost productivity, such as Prologic’s sorting and optimization scanners, log spacing control, a log rotator, curve sawing, optimized edging, high-speed feed, scan and set technology and fast setting changes. To ensure durability, the frames of the chipper canter were made of special steel, whereas previously the steel used in aircraft landing gear was used.

The new sawmill’s production target of 400,000 m3 was calculated based on two shifts a day for a five-day period. Tommi Sneck, Director of Koskisen’s Sawn Timber Industry, says there is room for growth in volumes before the line’s full capacity is reached.

“The sawing line comes with the DX option, which makes it possible to ramp up the line’s speed and use thinner kerf saws. Thinner kerf saws result in either a higher yield or a longer interval between blade changes. In Koskisen’s case, this would mean a production increase of as much as 200,000 cubic metres. More efficiency can also be achieved by adding circular saw blades to both the cantsaw and the ripsaw,” explains Sneck.

The line’s maximum speed is 180 metres per minute, but with DX sawing, the speed could even reach 230 metres per minute. Faster speeds are not the goal at least for the time being, since Koskisen’s line is meant for sawing larger logs.

“At least until the end of 2023, only large-diameter logs will be sawn,” says Sneck.

More options to choose from

The line’s scan and set technology combined with optimized production planning will open up entirely new possibilities from a sales standpoint. Log optimization will mean more products can be directed to processing and, for example, the constant headache sawmills face with regard to side boards will be eased.

“Previously, side boards could not be fully optimized and 3-metre logs could not be sawn. These limitations have now been eliminated, and particularly in our main market of Japan, where 3-metre-long products are in demand, customers will have more options,” says Sneck.

For customers, the new sawmill will mean not only new products, but also better quality.

“The products’ dimensional accuracy and technical quality will improve. For example, straightness will improve, as we will switch to using 11 drying sticks in the drying loads. As production volumes grow and errors decrease, deliveries will become more reliable,” states Sneck.

The sawmill’s scan and set technology and wider range of options will be a positive challenge for Koskinen.

“We need to rethink our production planning and get sales and production to coincide. This of course requires learning, but we already have good resources available,” says a pleased Sneck.